Has the times changed? Why are old crystal solidification machines at a loss when facing Mini LEDs?

2023-05-10(3526)Browse

The traditional LED display market is booming, but as human demand for visual experience continues to increase and technology continues to update and develop, Mini LED has emerged. LED leaders have stepped out of their original business areas, and the upstream and downstream of the industry chain have made bets. Apple is expected to launch Mini LED tablets and laptops in early 2021; Samsung has successively launched the Micro LED (Mini LED) The Wall series; Jingdian and Liyade invested to establish Lijing Microelectronics, formed an alliance with Longda, and invested heavily in the research and development and production of Mini LEDs. Not only that, according to experts, according to the News Center, in the first half of 2020, manufacturers in the upstream, midstream, and downstream of the cross-strait industrial chain invested in Mini LEDs.

It can be said that as a new generation of display technology, Mini LED has gradually become a prairie fire. However, as chip sizes become smaller and more important in the transfer and solidification process, traditional devices have encountered bottlenecks.

Recently, it was reported that Crystal Electric is significantly purchasing equipment specifically for high-speed transfer and solidification of Mini LEDs. Samsung is also searching for new Mini LED solidification equipment, and the traditional old double swing arm design has been excluded due to some defects.

So, what are the drawbacks of traditional old dual swing arm devices that make them unable to handle the fixed crystal of Mini LEDs and no longer considered by manufacturers?

According to experts from the Industry Research Center, the biggest drawback of traditional crystal solidification equipment using double arm swing arm welding heads is that the welding heads have no correction function and accuracy is difficult to guarantee. Simply put, in the process of transfer and solidification, two accuracies need to be ensured: solidification accuracy and angle accuracy. Fixed crystal accuracy XY refers to the precise matching between the chip landing point and the XY coordinate of the target fixed crystal position. Angle accuracy θ Refers to the precise matching of the angle between the electrode and solder joint contact surface of the flip chip. In addition, when the chip is cut off from the epitaxial layer and transferred to the blue film, there may be angular deflection, as well as pulling the blue film during the process of grasping the chip, which may further affect the accuracy of the solid crystal.

These issues can still be ignored in traditional LED packaging, as the size of traditional LED chips is large enough compared to Mini LEDs, ± 25? The crystal fixing accuracy XY of m differs by an order of magnitude compared to the size of traditional LED chips, so the resulting crystal fixing error has little impact.

But at the Mini LED stage, the chip size is about 200? Below m, the distance between chip electrodes is 100? Below m, ± 25? The solid crystal accuracy of m is XY and ± n+2? Angle accuracy of θ The resulting error will be significantly amplified. It can be said that the smaller the size of the Mini LED chip, the higher the requirement for crystal fixing accuracy.

The smaller the size of the Mini LED chip, the smaller the dot spacing or the smaller the proportion of light source area on the display screen, thereby improving the display effect. In addition, the price of Mini LED chips is positively correlated with the chip area. The smaller the chip area, the more chips each epitaxial chip can cut, and the lower the price of a single chip.

In order to pursue better display effects and lower costs, the future trend of Mini LED displays is towards chip size reduction. Therefore, rather than investing in equipment that appears to be cost-effective but will be phased out by the industry in the coming years, it is better to follow the rules and invest in the layout of new high-precision crystal fixing machines for Mini LEDs in advance, firmly grasping the first mover advantage.

New Information

-

AS3201 Bulk Component Mounter: Supporting LED Beads and Bulk Component Mounting at Any Pitch, and Improving Quick Changeover Efficiency

lEquipping dual vibrationfeeding, andsupporting0606–2121 LE...

-

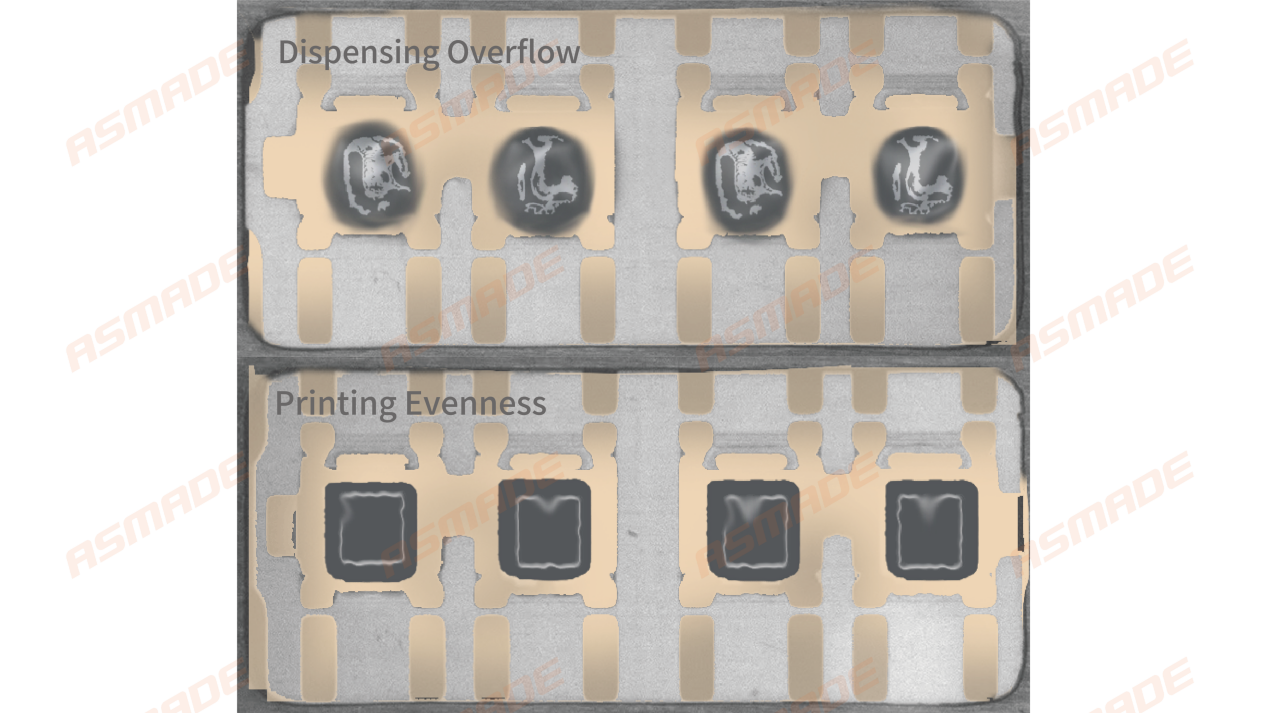

On-Chip Printing | Effectively Solving Dispensing and Printing Issues in Power Device Packaging

In theclip bonding packagingprocess of power devices, dispen...

-

Chip-Level Printer | Printing power device frames in the X axis direction, combined with on-chip printing technology

The world's first semiconductor chip-level printer with ...

-

Semiconductor Epoxy Die Bonder | Combining Spot Epoxy Process with Die Bonding Process in One Machine, Capable of Handling Numerous Products.

The Epoxy Die Bonder is a semiconductor machine that feature...

0755-29691921

Hotline:0755-29691921

Phone:0755-29691921

Fax:0755-29691921

Email:market@asmade.cn

Address:Building 3, Xifengcheng Industrial Park, Fuhai Street, Bao'an District, Shenzhen City, Guangdong Province

0755-29691921

0755-29691921